Whether you’re creating a new Bluetooth Low Energy (LE) product or updating an existing one, deciding whether to go with a chipset vs. a module is a very important decision.

What’s the difference between the two? And which one is best for you?

Summary Answer:

- SoC chipset is an IC that integrates a programmable processor, memory, and other essential peripherals onto a single silicon chip.

- A SiP module is an IC package that contains multiple ICs. An SoC is included inside this package.

- The primary difference between the two is that in an SoC, we group heterogeneous components onto a single chip; In a SiP, we group heterogeneous ICs onto a single package.

- SiPs allow for the easy addition of analog and RF features to digital CMOS, which may offer cost and performance benefits.

- Although SoC designs are typically smaller and less expensive to produce, design costs may be greater, and time-to-market is typically slower.

- Build or buy? Depending on the anticipated unit volumes, time to market urgency, risk tolerance, and available resources for each Bluetooth LE product, either approach may be appropriate.

Let’s unpackage the summary answer. Shall we?

SoC vs. SiP Module: The Basics

1. SoC

A system-on-chip, or SoC, is an integrated circuit that contains most of the essential components of a complete system on a single chip. It is the realization of a system’s entire functionality in a single IC.

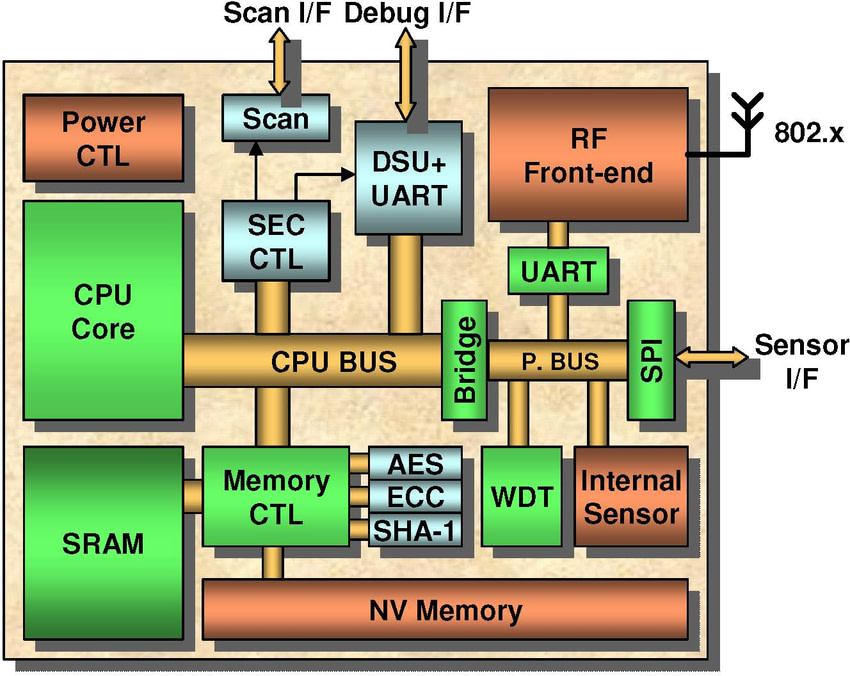

The general architecture of embedded core-based system-on-chip (SoC).

Source Resistive switching behavior in TiN/HfO2/Ti/TiN devices

SoCs contain most of the essential blocks a system needs to function. A typical SoC contains one or more general-purpose processors, one or more DSP processors, embedded memory, a protocol block, controllers for external memories, and various interface support circuitry.

Although an SoC does include a lot of things. There are some things it doesn’t have.

These include interface blocks that can’t be made with CMOS- or CMOS-compatible technologies. This includes interface blocks for displays, keypads, batteries, and more.

The Bluetooth LE market is rife with SoCs, which are utilized extensively. Check out the most popular SoCs on the market today (2022).

2. SiP Modules

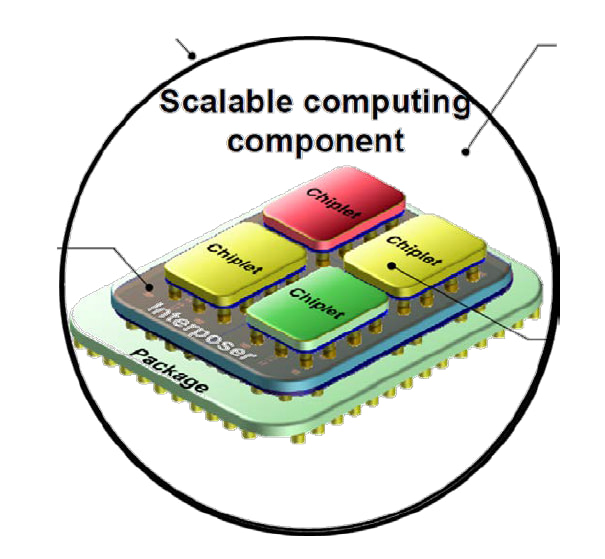

A system-in-package, or SiP, is a group of integrated circuits (ICs) with different functionalities, and passive and active components, enclosed in a single housing that acts as a system or subsystem.

Source: SiP and Module

These ICs (the largest ICs manufacturable at the highest yield and hence lowest cost) are usually connected using wire bonding or flip-chip technology.

One of the most significant advances observed in SiP is the ability to stack dies vertically 3D or horizontally, side-by-side, allowing the provision of multiple dies in a single package. This allows for a smaller form factor and higher density packaging.

Additionally, SiP offers more design freedom because it allows designers to combine numerous semiconductor technologies and reuse intellectual property from various sources, allowing them to overcome integration challenges without sacrificing chip technologies.

Another rising trend in SiP is integrating different types of devices such as passive and active components inside substrates. For example, Silabs’ BGM220S SiP modules have an antenna integration within the SiP module substrate.

Antenna Integration

The IoT industry is booming and one of the most frequently asked questions about Bluetooth LE-enabled IoT devices is their:

- size,

- radio performance,

- and pricing.

Ideally, engineers would want to build LE products with components as small and as cheap as feasible, with excellent RF performance.

Because necessity is the mother of invention, silicon manufacturing processes were improved to allow the integration of the MCU(Microcontroller Unit) and RF frontend into system-on-chip (SoC) configurations.

The creates small-sized wireless MCU required by the IoT applications where space is premium.

However, the bottleneck for a real wireless SoC is the realization of an on-chip antenna (OCA). The last challenge is antenna integration, which is not trivial.

Therefore, most available Bluetooth LE SoCs solutions are SoC transceiver designs. The RF transceiver is integrated into the chip, but the antenna is left for customers to sort out.

A person designing a Bluetooth LE product will face two choices: Build or Buy. Either purchasing an SoC and an external chip antenna and then integrating the two on their own (building) or buying a SiP module that has already integrated the SoC with the chip antenna.

Choice A: Using a Bluetooth LE SoC On The Product Printed Circuit Board

SoC designs are smaller and less expensive to produce. But they do have more design costs because trying to put an SoC and chip antenna together on the same product printed circuit board (PCB) is difficult.

But how hard can it be?

To create an SoC with an antenna matched for the actual end-application design, an experienced designer must answer some complex questions about the antenna, such as what type of antenna to use, the appropriate selection of packaging material to prevent antenna detuning, the position of the antenna in the design, PCB size, clearance areas and more.

The optimization of antenna performance and the SoC RF layout requires an understanding of the difficult RF design rules and the use of expensive equipment, software, and facilities to debug RF designs.

On top of all that are regulatory approvals and wireless standard certifications.

Wireless SoCs do not carry product-type approvals or pre-certifications. Therefore you will have to go through the entire approval and certification process on your own before commercialization.

Hidden Costs Associated with Choosing a Bluetooth LE SoC

For this design route, there are some hidden costs that you need to consider.

1. Pricing Trends

When buying components, you, as an individual customer, will have less pricing power than module vendors. This is because the latter aggregate the volume from many customers, giving them more negotiating clout.

So if you are building just a few LE products, procuring all the components needed to put the SoC on the board can be a little bit more costly.

2. Supply Chain Overheads

When using a module, you would only need one supplier to manage – the module vendor. But with an SoC, you need to manage the SoC vendor, as well as all the other component vendors.

These multiple suppliers have different lead times, product longevity, and other factors. All these together into a common supply chain require more resources to manage.

If you want to learn more about the hidden costs in SoC design-based products, read this white paper from Silicon Labs. It provides an insightful look at these costs.

Choice B: Using A Pre-Certified Bluetooth LE SiP Module In Your Design

A SiP module is a complete system in a package, integrating an SoC with one or more passive and active devices such as an antenna, filters, and power amplifiers (PA) into a single package.

The antenna size and position are optimized to work with the electronics inside the package, and modules come with well-documented layout guidelines for maximum RF performance.

Consequently, the complexity of RF design is eliminated. Modules offer plug-and-play solutions that can easily be integrated into LE products.

Additionally, with modules, getting RF regulatory approvals and wireless standard certifications is the job of the module manufacturer. So, you don’t have to worry about any of that.

Counterpole to the above advantages is that a SiP module costs more and is typically larger (in size) than its SoC equivalent.

Bluetooth LE SoC vs. SiP Module: Which is right for you?

Build or Buy? Depending on the anticipated unit volumes, time to market urgency, risk tolerance, and available resources for each Bluetooth LE product, either approach may be appropriate.

1. Example Use Cases when a SiP Module is a Better Strategy than an SoC :

Oftentimes, the decision of whether to use a SiP module or an SoC can be boiled down to a question of cost. However, as Omer Sheena from Dialog Electronics pointed out in the recent SoC vs. Module webinar, the choice also depends on strategy and business needs.

Below are examples of two use-case scenarios where the benefits of a SiP module justify the additional expense.

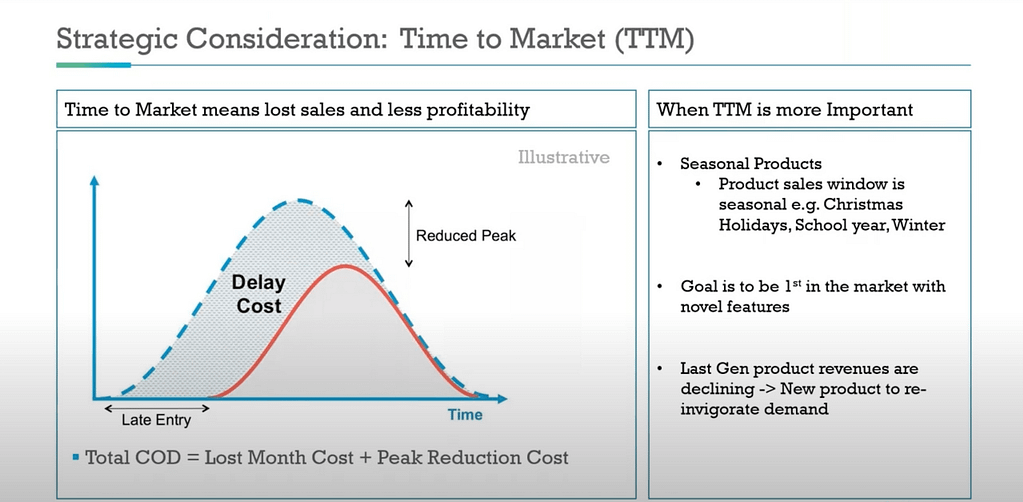

A. When Time to Market (TTM) is more important

TTM or time-to-market is the amount of time it takes from when a product idea is conceived to when it is available for consumers to purchase. A SiP module is usually preferred over an SoC when TTM is more important.

This could be the case if:

- Your product is seasonal

- The goal is to be 1st in the market with novel features

- Last generation products are declining, and you are using the new product to reinvigorate demand.

Source: Module or SoC Webinar by Dialog Semiconductors

With an SoC, you would have to worry about antenna design, regulatory approval, and wireless certification. These are all time-consuming tasks that can push back your TTM and can therefore cause you to lose certain months in the market.

Every day the product is not on the market is a day of lost revenue.

So, is TTM critical for you? Can you handle the market late entry cost? Can you handle the reduced peak?

B. When the main electronics board is used for both LE devices and non-LE devices

Let’s take the example of a “dumb” plug v1. and and “Smart” plug v2.

Assume the “smart” plug uses the LE for connectivity and also that both devices use the same main electronics board. The only difference between them is that one has an LE connectivity option and another doesn’t.

In such circumstances, a module is usually ideal since it provides a plug-and-play solution that allows you to reuse the main electronics board across both product lines without starting from scratch as you would if you used an SoC.

2. Module Vs. SoC Consideration Table

| You might want to consider an SoC when | You might want to consider a SiP Module when |

| It is important to have the lowest possible BOM. | Fast time to market is very important |

| You have RF Engineers on staff | You have limited RF Engineering on staff |

| You own RF lab equipment and tools | You have limited RF lab equipment or tools |

| There is ample time for prototypes to optimize antenna | There is no appetite for RF design risk on TTM |

| You have experts and/or budget for wireless standards compliance testing | You have limited experience in wireless standards compliance testing |

| You have experts and/or budget for regulatory approvals | You have limited experience with regulatory approvals |

Source: Silicon labs

Steps For Making a Module Vs. SoC Cost and Break-Even Analysis

How do you run a cost analysis to see which option makes sense for your business?

Let’s review the steps needed to do a module vs. SoC cost and break-even analysis.

1. Step One: Understand and Estimate the Cost

Find the price of buying the required SiP modules. Estimate the overall cost of building a module in-house. Your overall cost of building a module in-house should reflect an estimate of:

- The component cost of SoC

- Test and RF Engineering costs, samples, lab equipment, etc.

- Certification costs

- Supply-chain overhead

2. Step Two: Estimate the number of LE product units you expect to sell

Research and identify the total available market (TAM) size and expected growth, and then roughly estimate the number of LE product units you expect to produce and sell.

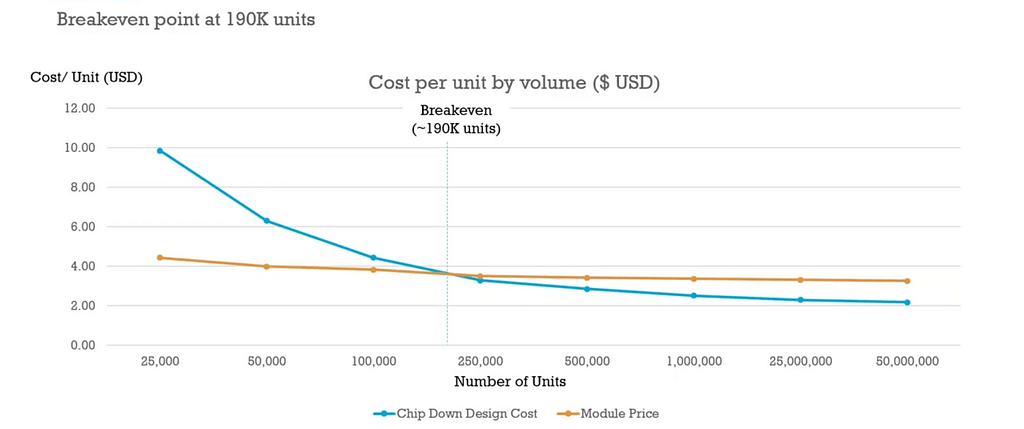

3. Step Three: Use the Cost per Unit formula

A cost per unit volume (CUV) is the total cost of a product or service divided by the total quantity of that product or service sold/made. This metric is often used in business to track the efficiency of production.

The goal is to have a low CUV so that you can pass on the savings to the customer and entice more customers to buy (or take home more money if you’re able to sell your product at a premium).

Calculate your CUV and create an excel graph with the number of units you expect to produce and sell on the x-axis and their associated cost per unit on the y-axis.

You will get something that looks like this:

Source: Module or SoC Webinar by Dialog Semiconductors

For this particular example, for 25,000 units, it makes more sense to use a module over an SoC. At 190,000 units ( break-even) point, it doesn’t matter if you use an SoC or a module because the price is almost the same.

But you can see that with a volume beyond 250,000 units, using an SoC starts to get cheaper than buying a SiP module.

So generally, the best option changes with the volume of products you intend to sell.

Conclusion

In the end, it’s important to weigh all of the factors involved to make the best decision for your product.

Luckily, most SoC or module vendors have a sales and support team that can help you with the decision-making process and can give you more insights into what to expect in terms of cost, schedule, and product quality.