Sponsored by Raytac Corporation.

In the world of wireless connectivity, Bluetooth Low Energy (Bluetooth LE) continues to dominate the IoT landscape, powering a vast range of applications, from wearables and smart home devices to industrial sensors and medical equipment. As Bluetooth LE evolves, manufacturers are constantly pushing the boundaries of performance, security, and energy efficiency.

With the release of Nordic Semiconductor’s nRF54 series, Bluetooth LE developers now have access to next-generation capabilities featuring higher processing power, ultra-low power consumption, and improved security protocols.

One of the most exciting implementations of this new chipset is found in Raytac’s AN54L15Q, a pre-certified Bluetooth LE module that significantly reduces development complexity by handling RF design, regulatory compliance, and antenna tuning—allowing developers to focus on building their applications rather than wrestling with low-level RF challenges.

In this blog post, we will:

- Take a first look at the Raytac AN54L15Q, its companion development board (AN54L15Q-DB), and how it simplifies Bluetooth LE development.

- Also, compare module-based designs vs. chip-down approaches, providing insights into cost, certification, scalability, and engineering effort to help you decide which approach best fits your project.

- Highlight how Raytac provides benefits beyond just the typical module-based ones.

Unboxing the Raytac AN54L15Q-DB Development Board

In any Bluetooth LE development project, having a robust, easy-to-use development board can significantly accelerate the prototyping process.

The AN54L15Q-DB is designed specifically for this purpose, providing a plug-and-play experience that eliminates the need for custom PCB design during the early stages of development.

Inside the Box

Opening the AN54L15Q-DB kit, you’ll find:

- AN54L15Q-DB Development Board – featuring the AN54L15Q module pre-mounted, along with a built-in antenna, debug connectors, and expansion headers.

- 1x IDC Ribbon cable

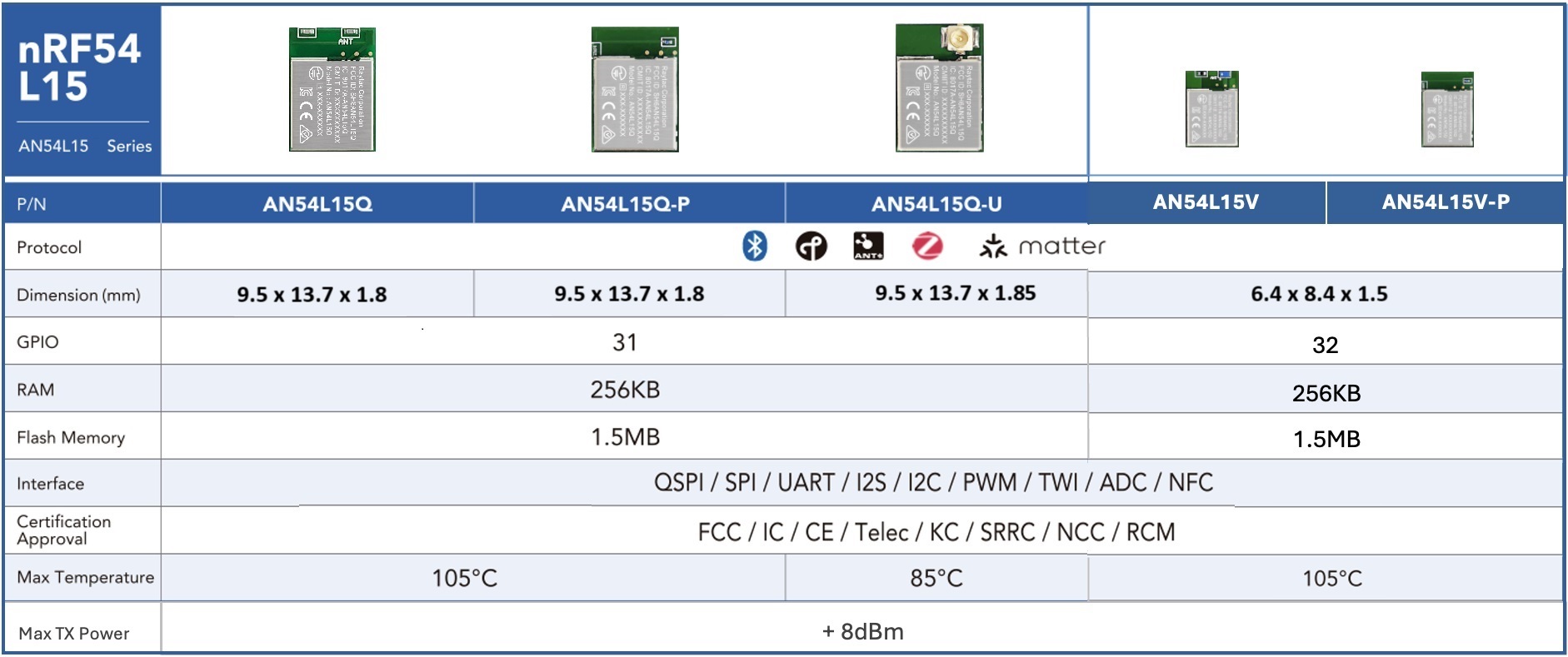

There are multiple module options from Raytac featuring the Nordic nRF54L15 SoC:

The focus of this blog post will be on the AN54L15Q, which features the QFN packaging and a built-in chip/ceramic antenna.

Other QFN modules are available and provide a PCB/printed antenna option (AN54L15Q-P) and a U.FL connector for an external antenna option (AN54L15Q-U). There are also a couple of WLCSP-based modules that will soon become available (AN54L15V and AN54L15V-P).

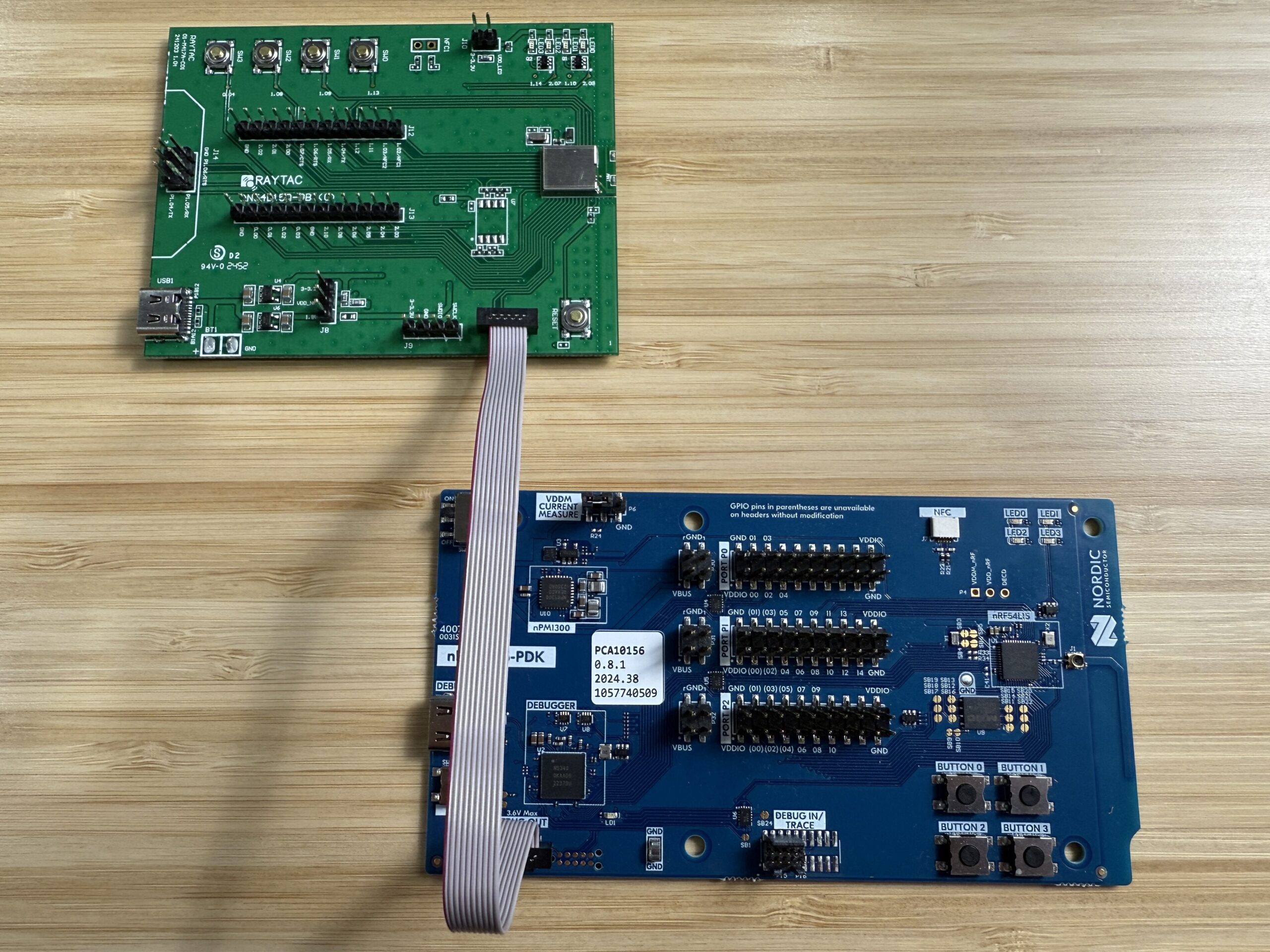

To interface with the module (that's mounted on the development board), Raytac recommends the use of a Nordic nRF54L15 DK, which provides the debug and flashing capabilities.

The Nordic DK also provides developers with a way to perform a rough comparison of the RF performance between it and the Raytac module.

Note: while developers can use a J-Link tool to debug and flash the module, the solution would be at least 10 times more expensive than using the standard nRF54L15 DK from Nordic Semiconductor. There is also no guarantee that all versions of J-Link devices would work out of the box. The nRF54L15 DK method is the officially supported and recommended method.

So, to summarize, to get started with development using the AN54L15Q-DB, you'll need:

- The AN54L15Q-DB itself

- The IDC Ribbon cable

- A Nordic Semiconductor nRF54L15 DK

- Two USB-C cables to connect the AN54L15Q-DB and the nRF54L15 DK to the computer

Getting Started with the AN54L15Q-DB

Setting up the AN54L15Q-DB is straightforward:

- Connect the two boards via the IDC ribbon cable (J1 on the AN54L15Q-DB to the "Debug Out" port on the nRF54L15 DK).

- Connect each of the boards to your computer via a USB-C cable.

- Install the necessary software packages (used for standard Nordic development), including VS Code, nRF Connect VS Code Extension, and the Segger J-Link software.

Once this is done, developers can immediately begin working with Nordic’s nRF Connect SDK, an extensive software framework for Bluetooth LE development. For those already familiar with Nordic Semiconductor’s nRF SDK, the development experience will feel natural, as it fully supports Nordic’s firmware ecosystem, including power management, security, and Bluetooth LE stack integration.

A key advantage of the AN54L15Q-DB is its built-in RF design, allowing developers to test Bluetooth LE performance without additional tuning. This makes it an ideal reference platform for companies planning to integrate the AN54L15Q module into their own products.

Hands-On Tutorial: Running a Sample Application

Important Info:

Nordic DevAcademy Lesson for setting up nRF Connect SDK: https://academy.nordicsemi.com/courses/nrf-connect-sdk-fundamentals/lessons/lesson-1-nrf-connect-sdk-introduction/topic/exercise-1-1/

To fix the error for the absent external flash on the demo board, you can add the lines highlighted below:

#

# Copyright (c) 2018 Nordic Semiconductor

#

# SPDX-License-Identifier: LicenseRef-Nordic-5-Clause

#

CONFIG_NCS_SAMPLES_DEFAULTS=y

# Disable External Flash (for AN54L15Q-DB)

CONFIG_SPI_NOR=n

CONFIG_BT=y

CONFIG_BT_PERIPHERAL=y

CONFIG_BT_DEVICE_NAME="Nordic_LBS"

# Enable the LBS service

CONFIG_BT_LBS=y

CONFIG_BT_LBS_POLL_BUTTON=y

CONFIG_DK_LIBRARY=y

CONFIG_SYSTEM_WORKQUEUE_STACK_SIZE=2048The Case for Bluetooth LE Modules vs. Chip-Down Design: A Comprehensive Comparison

One of the most critical design decisions when developing a Bluetooth Low Energy (Bluetooth LE) product is choosing between a pre-certified module or a chip-down approach. This choice impacts everything from cost and scalability to engineering complexity, time-to-market, and regulatory compliance.

In this section, we will break down the key factors that influence this decision, exploring when it makes sense to use a module and when a chip-down approach is the better option.

1. Regulatory & Certification Requirements

Regulatory compliance is one of the biggest hurdles in Bluetooth LE development. Depending on the country and product category, a Bluetooth LE-enabled device may need to pass multiple certification processes, including:

- FCC (United States) – Part 15C unlicensed wireless testing.

- CE/RED (Europe) – Compliance with the Radio Equipment Directive.

- ISED (Canada) – Wireless certification requirements for North America.

- Telec/MIC (Japan) – Radio Wave for telecommunication conformity system.

- ANATEL (Brazil), SRRC (China), WPC/TEC (India) – Region-specific requirements.

Using a Bluetooth LE Module (e.g., Raytac AN54L15Q)

A pre-certified module simplifies regulatory compliance significantly. Since the RF section, antenna, and transceiver are already tested and approved, the host product typically only needs minimal EMC (Electromagnetic Compatibility) testing. This can save thousands of dollars and months of testing time!

In addition, Raytac also provides an easy path for upgrades from one module to a newer one. The customer can inherit the same FCC/IC/TELEC/KC ID from Raytac for their newer product(s) and not worry about obtaining a new RF wireless certificate/RF circuit design on the mother PCBA.

Going Chip-Down (Using nRF54L15 SoC Directly)

A chip-down design means you are responsible for full certification. This includes:

- RF compliance testing

- Antenna performance validation

- Conducted and radiated emissions testing

Each of these tests adds cost and complexity. Failing any part of the certification process means redesigning hardware and retesting, causing potential delays of 3-6 months.

In contrast to going the Raytac module route, in the case of upgrading the product to a newer design, the manufacturer will have to perform total RF circuit design, including antenna matching, in addition to the RF compliance test & certification procedures. This not only involves new compliance testing but also the R&D effort necessary to prepare the system for these new tests.

Verdict: Bluetooth LE Modules offer a massive advantage for companies that want faster compliance and reduced regulatory costs.

2. Cost Breakdown & Scalability

One of the main reasons companies consider a chip-down approach is to reduce per-unit costs at high production volumes. However, the total cost of development also includes:

| Cost Factor | Bluetooth LE Module (AN54L15Q) | Chip-Down (nRF54L15 SoC) |

|---|---|---|

| RF Certification | Pre-certified (~$0) | $10K–$100K+ (region-dependent) |

| PCB Design | Simpler, fewer RF layers | Requires expert RF design |

| Antenna Tuning | Pre-optimized | Needs lab testing & tuning |

| Component Costs | Higher per unit | Lower per unit at scale (>100K units) |

| Manufacturing Cost | Simpler assembly | More complex PCB fabrication |

| Time-to-Market | Faster (~3–6 months saved) | Longer (~6–12 months) |

When Modules Make Sense

- Low-to-medium volume production (<100K units/product)

- Startups, IoT devices, medical devices, industrial sensors

- Limited RF engineering expertise

- Time-sensitive projects (product launches, MVPs, Kickstarter campaigns)

When Chip-Down Designs Make Sense

- High-volume manufacturing (100K+ units/product)

- Optimizing unit cost for large-scale production

- Companies with in-house RF engineers

- Custom antenna designs or size constraints

Rule of Thumb: If you’re producing less than 100K units/product, a module is usually the better financial choice due to the lower NRE (Non-Recurring Engineering) costs.

3. Engineering Effort & Expertise Required

The level of RF and PCB design expertise required for a Bluetooth LE product varies greatly depending on whether you choose a module or go chip-down.

Using a Bluetooth LE Module (e.g., AN54L15Q):

- No RF expertise is required

- Pre-optimized RF performance – Antenna placement has already been validated.

- No manual tuning or debugging needed – The module is pre-tested for Bluetooth LE signal integrity.

- Faster development cycles – Developers can focus on firmware and application logic rather than hardware design.

Going Chip-Down (Using nRF54L15 SoC):

- Requires experienced RF engineers to design and optimize the antenna layout.

- PCB design is more complex due to RF shielding, ground planes, and impedance matching.

- RF debugging tools (e.g., spectrum analyzers) are required, which can cost thousands of dollars.

- Any small mistake in the PCB layout can degrade Bluetooth LE performance and require redesigns.

Verdict: Bluetooth LE Modules significantly reduce the engineering effort and technical risks.

4. Global Market & Module Policies

Certain countries support modular certifications, while others require full device testing, even if a certified module is used.

| Region | Module-Friendly? | Certification Required for Chip-Down? |

|---|---|---|

| United States (FCC) | ✅ Yes | ✅ Full certification |

| Canada (ISED) | ✅ Yes | ✅ Full certification |

| Japan (MIC) | ✅ Yes | ✅ Full certification |

| Korea (KC) | ✅ Yes | ✅ Full certification |

| Taiwan (NCC) | ✅ Yes | ✅ Full certification |

| European Union (CE/RED) | ❌ No | ✅ Full certification |

| Australia and New Zeland (RCM) | ❌ No | ✅ Full certification |

| Brazil (ANATEL) | ❌ No | ✅ Full certification |

| India (WPC/TEC) | ⁉️ It depends! See note below* | ✅ Full certification |

| China (SRRC) | ⁉️ It depends! See note below* | ✅ Full certification |

* Modules are considered approved or unapproved for these regions based on the end product type.

Key Takeaway: In non-module-friendly countries like the EU, Australia and New Zealand, China, India, and Brazil, even if you use a pre-certified module, the end product must still undergo full RF testing.

The good news? Even for non-module-friendly regions, Raytac can help streamline the certification process for their customers, reducing the cost, stress, and time involved with RF certifications in these regions.

Final Verdict: Module or Chip-Down?

If you're a startup, small business, or developing an IoT device that will ship in low-to-mid volumes, Raytac’s AN54L15Q Bluetooth LE module is the smarter choice. It simplifies RF design, reduces certification costs, and accelerates time-to-market.

If you are manufacturing a large volume of units (100K+ units per product in the case of Bluetooth and around 600K+ units in the case of Wi-Fi) and have RF engineering expertise, a chip-down approach could reduce unit costs but requires significant investment in design, tuning, and certification.

Choosing the Right Path

- Need fast development with minimal risk? → Go with a Bluetooth LE module.

- Shipping globally and want easier compliance? → Use a pre-certified module.

- Have an in-house RF engineering team and mass production scale? → Consider chip-down.

For most companies, a module like the AN54L15Q is the best balance of cost, simplicity, and scalability.

The Raytac Advantage: Certifications and Beyond

Beyond just offering pre-certified modules, Raytac also offers their customers a few additional complimentary services to ensure their success in launching their products to market in the shortest time possible. These include:

- Schematic diagram review

- PCB layout circuit review

- Radio test sample preparation

When planning to launch a device worldwide, there are a few aspects to keep in mind:

- RF Wireless Regulations

- Communication Protocol Licenses and Certifications (Bluetooth, Wi-Fi, etc.)

- EMC (EMI + EMS)

- Industrial Field and Safety Tests

Raytac offers customers help with #1 and #2 above. Let's cover these points in more detail.

RF Wireless Regulations

- For module-friendly regions, customers minimal work is needed to achieve RF certification since Raytac offers pre-certified modules.

- For non-module-friendly regions, Raytac helps customers streamline the radio testing and certification process by partnering with SGS, a world-renowned test lab.

The process works as follows:

- Customers will send their product sample(s) to Raytac.

- Customers will inform Raytac what test samples they need to provide the test house (Raytac also helps customers determine this information by consulting with RF experts).

- Raytac will prepare the product sample for the required radio tests and send it to the testing lab.

- Raytac works exclusively with SGS, a world-known test laboratory, to streamline the radio testing process and certify the product for worldwide coverage.

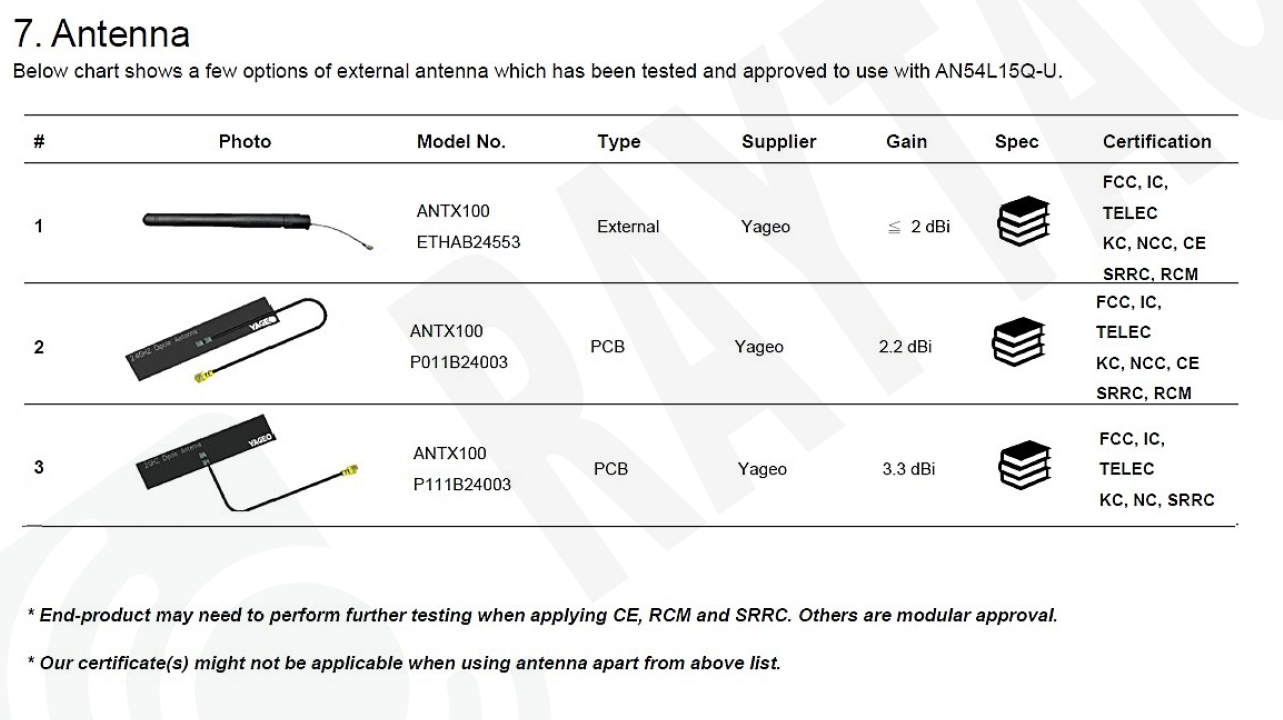

External Antenna Options

Raytac also offers customers recommendations for external pre-certified antennas (PCB or u.FL connector-based) if they decide to incorporate these into their product. The antennas are shown in the following table:

Communication Protocol Licenses and Certifications (Bluetooth, Wi-Fi, etc.)

The costs and effort/time associated with obtaining licenses and certifications for the wireless protocols used in a product can really pile up when going with the chip-down approach. As we already covered earlier, product makers can significantly reduce costs and time by using a pre-certified module.

When designing a Bluetooth-enabled product, manufacturers must comply with the Bluetooth Special Interest Group (Bluetooth SIG) qualification process. The Bluetooth Qualification Program (BQP) ensures that all Bluetooth devices meet interoperability, compliance, and quality standards, allowing them to use the Bluetooth trademark legally.

Using a pre-certified Bluetooth module significantly simplifies this process and reduces costs, time, and engineering effort compared to developing a chip-down solution.

To qualify a Bluetooth product, manufacturers must complete one or more of the following qualification pathways:

1. Qualification of a New Bluetooth Product (Chip-Down Approach)

- Requires testing at a Bluetooth Qualification Test Facility (BQTF).

- Time-consuming and expensive, especially for small teams.

2. Qualification of an End Product Using a Pre-Certified Bluetooth Module

- Most of the qualification process is already completed if a pre-qualified module is used.

- The manufacturer inherits the module’s existing qualification.

- It only requires a simplified listing rather than full testing.

- Much faster and more cost-effective.

- Using a module pre-tested by a BQTF (Bluetooth Qualification Test Facility) ensures reliable Bluetooth performance without requiring in-house RF engineers.

For Wi-Fi, it is a completely different ball game and involves much higher costs when designing using a chip-down approach.

To summarize, a pre-certified module is the fastest and most cost-effective path to market if you’re designing a Bluetooth LE-enabled product and want to avoid expensive Bluetooth testing. For most companies, using a pre-certified module is the best balance of efficiency, compliance, and performance.

Summary

Developing a Bluetooth Low Energy (Bluetooth LE) product requires balancing cost, development effort, regulatory compliance, and time-to-market. Whether you are a startup, an IoT manufacturer, or an enterprise scaling production, choosing between a pre-certified Bluetooth LE module like the Raytac AN54L15Q or a chip-down design using the Nordic nRF54L15 SoC is a critical decision.

After analyzing key factors such as engineering effort, certification, cost, scalability, and Bluetooth qualification, here’s what we’ve determined:

If speed, simplicity, and regulatory compliance are priorities, the Raytac AN54L15Q module is the best choice for most developers.

- Faster Time-to-Market – Avoids RF tuning, antenna design, and certification delays.

- Pre-Certified for Bluetooth & Regulatory Compliance – FCC, CE, IC, MIC, RCM, and Bluetooth SIG certified.

- Minimal RF Engineering Effort – The RF front-end, power management, and antenna tuning are already optimized.

- Cost-Effective for Small-to-Medium Volume Production – Best suited for <100K units/product.

- Bluetooth SIG Qualification Simplified – Eliminates the need for full-stack testing and reduces Bluetooth certification costs.

- Global Market Readiness – Eases entry into module-friendly countries (FCC, MIC, ISED, KC, NCC).

For most companies, using a pre-certified module eliminates major risks associated with RF tuning, Bluetooth interoperability, and compliance testing.

Use a Bluetooth LE Module (Raytac AN54L15Q) if:

- You need fast product development with minimal RF engineering effort.

- You want to avoid high certification costs and simplify Bluetooth SIG qualification.

- Your expected production volume is less than 100K units/product.

- You lack an in-house RF engineering team or need global regulatory compliance.

Go Chip-Down (nRF54L15 SoC) if:

- You have RF engineering expertise and can handle PCB layout, antenna tuning, and compliance testing.

- You are producing 100K+ units per product, and unit cost is the top priority.

- Your design requires custom RF tuning, shielding, or ultra-low power optimizations.

The Raytac AN54L15Q Bluetooth LE module provides the best balance between performance, cost, and time-to-market for most IoT, wearable, and industrial Bluetooth LE applications.

If you’re considering using the Raytac AN54L15Q in your next Bluetooth LE product, check out the following resources:

- Raytac AN54L15Q Product Page

- Raytac AN54L15Q Modules:

- AN54L15Q: deployed Chip Antenna, which offers excellent connectivity.

AN54L15Q-P: deployed PCB antenna and offers good connectivity.

AN54L15Q-U: deployed u.FL connector for External Antenna and offers a super long-range connectivity ability

- AN54L15Q: deployed Chip Antenna, which offers excellent connectivity.